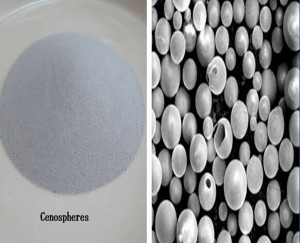

Cenosphere/Hollow Ceramic Microspheres

Cenosphere(Hollow Ceramic Microspheres) are lightweight, inert, hollow, nonmetallic spherical materials,composed largely of silica (SiO2) and alumna (Al2O3) compositions,similar with glass and ceramic.

Compared to irregular-shaped and partially-spherical fillers, the 100% spherical shape of Ceramic Microspheres,

provides improved processing and performance. Being inert it is not affected by solvents, water, acids or alkalis.

75% lighter than other minerals currently used as a filler or extender.

Color: range from gray to light gray.

Features:

• Spherical Shape • Ultra Low Density • Heat Resistance

• Improved Flowability • High Insulating • Low-Cost

• High Strength • Chemical Inertness • Good Sound Isolating

• Low Thermal Conductivity • Low Shrinkage • Reduced Resin Demand

Chemical Composition:

|

Al2O3 |

SiO2 |

Fe2O3 |

CaO |

MgO |

K2O |

Na2O |

TiO2 |

|

25-35 |

50-65 |

2.0 |

0.2-0.5 |

0.8-1.2 |

0.5-1.1 |

0.03-0.9 |

1.0-2.5 |

Physical Property:

|

Grade No. |

TS-(20-70) |

TS-40 |

TS-50 |

TS-60 |

TS-100 |

TS-150 |

|

Particle Size |

210-850μm |

500μm |

300μm |

250μm |

150μm |

100μm |

|

Floating Rate% |

≥95.0 |

≥95.0 |

≥95.0. |

≥95.0 |

≥95.0 |

≥95.0 |

| Bulk Density g/cc |

0.35-0.45 |

0.35-0.45 |

0.35-0.45 |

0.35-0.45 |

0.35-0.45 |

0.35-0.45 |

|

Moisture% |

<0.5 |

<0.5 |

<0.5 |

<0.5 |

<0.5 |

<0.5 |

|

Fire-resistant Degree ℃ |

1600-1700 |

1600-1700 |

1600-1700 |

1600-1700 |

1600-1700 |

1600-1700 |

Specification:

20-70mesh 40mesh 50mesh 60mesh 80mesh 100mesh 150mesh.etc.

Application: Cenospheres have been shown to improve performance,reduce VOCs,increase total solids

and reduce costs in a wide range of applications,including:

| Paint&Coatings | ink,bond,vehicle putty, insulating, antiseptic, fireproof paints. |

| Constructions | speciality cements, mortars, grouts, stucco, roofing materials, acoustical panels, coatings, shotcrete, gunite. |

| Plastics | BMC and SMC molding compounds, injection molding, modeling, extrusion, PVC floors, foils,nylon, HDPE, LDPE, polypropylene. |

| Foundry&Refractory | refractories, castables, tile, fire bricks, aluminium cement, insulating materials,coatings. |

| Automotive | composites, undercoats, tires, engine parts,brake blocks, decorative bars, body fillers, plastics, damping materials. |

| Oil Manufacturing | oil well cements, drilling muds,grinding materials,lost circulation aids,explosives. |

Packing: In 20kgs,25kgs net kraft paper bags;or 500kgs/600kgs/1000kgs big bags.